Evolution of 3D Printing Technology Raises Security Concerns

Introduction

Also known as the term additive manufacturing (AM), 3D printing is a process for making a three-dimensional object of almost any shape starting from a 3D model or other electronic data source.

Through additive processes, a 3D printer adds successive layers of material to compose the final shape under the control of a computer. This means that these industrial robots could be used to create customized objects on demand.

These technological jewels could be used practically in any industry. It is necessary to have only a digital representation of the object that must be realized to build it.

The reduction of the cost of 3D printers is extending their diffusion also within home users and hobbyists that could design and make new devices with a limited budget in a short time.

The first 3D printers appeared in the 1980s. Over time, the technology rapidly evolved and several models of 3D printers appeared on the market. Today a sophisticated extrusion-based printer is sold for $2,500-$3,000, but new models are appearing on the market having a cost of few hundreds of dollars. The new generation of 3D printers is very attractive for the industry due to its cost, considering that laser stereo lithography devices ordinarily used in most industrial systems are about 10-100 times more expensive.

3D printers represent the ideal choice for low to medium volume applications and eliminate the need for production tools.

Other benefits of the adoption of 3D printing processes are the energy saving technology and the optimal management of the material used for the production, which allows utilizing up to 90% of standard materials, with a significant reduction of waste.

"Furthermore, 3D printing is showing great promise in terms of fulfilling a local manufacturing model, whereby products are built on demand in the place where they are needed — eliminating huge inventories and unsustainable logistics for shipping high volumes of products around the world."

The use of 3D printers allows a significant reduction of time and costs for the realization of prototypes in industrial productions, and the availability of prototypes in a short time has the advantage of identification of design errors in the early stages of any manufacturing process.

Robert Schouwenburg, co-founder of Shapeways, an online firm that uses 3D technology to manufacture custom-made objects using several materials, declared that his company is now selling 50,000 products every month online, and the number of objects produced is in constant increase.

3D Printers, cheap and dangerous

3D printers, as expected, have attracted the interest of organized crime. Such devices may allow criminal gangs to print a weapon or any other object that can be used for illegal activities.

Public opinion was not considering 3D print as a threat until media agencies divulged the news that a man succeeded in the building of a plastic gun from a 3-D printer and firing at least one shot with it.

Cody Wilson is the name of the man that demonstrated the world's first fully 3D printed gun last year. He explained that anyone can create a lethal firearm just using a blueprint file of the weapon and a 3D printer.

The news alarmed authorities because such a weapon could avoid detection of metal detectors, and plastic guns could be designed by splitting the overall weapon in small components not easy to recognize by a visual inspection or an X-Ray.

The availability of this technology at reasonable prices was a turning point in the criminal ecosystem. A 3D printer can be bought for nearly $1,500. As a consequence, we assisted in the rapid proliferating of these devices.

Criminals could print a weapon like a gun or an AR-15 assault weapon at their home, choosing the most appropriate material from plastic to metal. However, 3D printers could be used for many other malicious purposes, such as to print components not easily affordable on the market. Let us think for example of the exploitation of 3D printers to make components blocked by an embargo.

Another argument of interest to law enforcement is the use of 3D printers for the production of counterfeit products. Criminal gangs could be interested in creating counterfeit products or device parts for making profits, but security experts are more worried by the possibility that those components could be used for sabotage. Counterfeit products could be introduced into the supply chain in order to cause anomalies and faults in the products designed. Highly sophisticated European criminals gangs operating worldwide have been using 3D printers to operate illegal activities on a large scale. How do they operate? Which are most attractive products in the criminal underground?

A metal gun for a little over a thousand dollars

More than a year after the presentation of the first prototype of 3D printed gun, Cody Wilson revealed that the "maker" movement has enabled anyone to create a metal weapon. Wilson's creation is known as the Ghost Gunner, a machine that can carve digitally-modeled shapes into polymer, wood or aluminum. The amazing news it that the machine is proposed on the market by Wilson's organization known as Defense Distributed for $1,200.

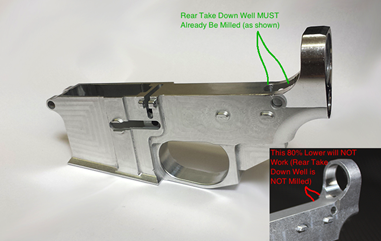

The project allows the design of the lower receiver component of an AR-15 that is the main component for a gun control firestorm. Despite that the lower receiver is just a component of the overall weapon, the other pieces could be acquired from online gun shops. In this way, anyone could create in total anonymity his own weapon (for this reason it is called "ghost gun") with no serial number and no background check.

Figure 1 - 3D printed gun component

Figure 2 - Ghost Gunner Video

https://www.youtube.com/watch?v=xwRtll3jjU4

Defense Distributed's controversial creations have included 3D printable plastic magazines and lower receivers for AR-15s as well as an entire 3D-printed pistol the organization called the Liberator.

In 2012, the Defense Distributed prototyped rifle receivers for the popular AR-15. A few months later it had created the gun file repository DEFCAD and released the files for the first printable AR-15 standard capacity magazines. In March 2013, it released the files containing the creation of first durable printed AR-15 rifle receiver.

In the same year, the organization issued the files for the Liberator pistol, which raised a heated discussion on free circulation of files for gun printing.

The Liberator pistol isn't the only example of a 3D-printed weapon. A 3D rifle dubbed "The Grizzly" was designed in Canada, and another a revolver named 'Zig Zag' was produced by Yoshitomo Imura, who was recently arrested in Japan for owning 3D-printed firearm components.

As explained in a blog post published by the Daily Mail, quoting a YouTube user named Duce, "a big misconception is that 3D printing and making guns using 3D printers are easy to make … We have been doing this for years and I can say it's not easy."

Duce revealed that his group has been working on making 3D components for guns for about two years. It is a question of time, but soon they will reach excellence in designing 3D printable guns.

Figure 3 - 3D printer blueprint

Is manufacturing a firearm legal?

The website of Defense Distributed provides an affirmative reply to the question, sustaining that "semi-automatic firearms, including the AR-15 lower receivers, are generally legal to manufacture for private individuals per US federal law Title 18 [which doesn't require serialization or other maker's marks]."

In effect, in December 2013 Congress voted to renew a ban on completely plastic guns that aren't visible to metal detectors and X-ray machines, according to The Associated Press.

Defense Distributed designed its 3D-printed handgun including a 6-ounce piece of steel within its entirely plastic firearm to allow its detection from metal detectors and ensuring the weapon was in compliance with the US Undetectable Firearms Act .

Apart from this ban, there aren't any other restrictions on plastic guns. Anyway, many states in the US like New York and California have introduced specific laws that aim to hinder the design of such weapons, regulating or banning the manufacture of 3D-printed guns.

A real case

Recently the Daily Mail demonstrated the security risk posed by a 3D printed weapon. Its staff built a gun that is capable of firing 0.38-calibre bullets, and the team of reporters made it using blueprints available on the Internet. They used a £1,700 machine to 'print' the components of the weapon and completed the work in just 36 hours.

Once they created the weapon, they smuggled it on to a packed Eurostar train.

"Two reporters passed completely unchallenged through strict airport-style security to carry the gun on to a London to Paris service in the weekend rush-hour, alongside hundreds of unsuspecting travelers," states the post published by the Daily Mail.

This scenario shows the dangers at the international level for the printing of such weapons that are composed by all the parts made with plastic and not easy to be recognized if packed separately. In the specific case, the entire gun did not trigger the metal detectors all Eurostar passengers must pass through.

3D printers and credit card fraud

Law enforcements in various countries have recently discovered the illegal activity of a highly sophisticated European ring of criminals that are using 3D printers to manufacture fake plastic card slot bezels. The criminals used 3D printer technology to build the card slot bezels to install on Automated Teller Machines (ATMs) and capture credit card data directly from a POS system.

The criminal gangs operated in Europe (Italy, France, Spain, Germany, and Turkey), and their capture was possible thanks to the joint operation, called "Operation Imperium", of law enforcement of different states, including Spain and Bulgaria and the European Cybercrime Centre (EC3).

Figure 4 - Criminals gangs arrested in Operation Imperium

According to the law enforcement agencies, the criminal network was involved in:

- ATM skimming

- Electronic payment fraud

- Forgery of documents

The organization of the group was very articulated; law enforcement made 31 arrests and seized eight different labs that were equipped with 3D printers, micro camera bars, card and magnetic strip readers, and plastic card templates.

Law enforcement agencies have noticed an increase of activity of criminals based in the 3D printing technology. The criminal ecosystem started to use the technology to print all kinds of furnishings for their needs. Not only weapon printing, but also credit card fraud instruments, keys that can open high-security locks, and many other products were produced by the criminals. In many cases, criminals have shared or sold 3D printing projects with other gangs, allowing the evolution of an underground movement specialized in 3D printing technologies.

In theory, they could also be used to build advanced weapons or to counterfeit machinery parts intended to break and cause catastrophic failure.

Counterfeiting and sabotage

As explained before, 3D printing represents an excellent technology for counterfeiting. It is not so complicated to reproduce any kind of object everywhere in the world and export it as a legitimate one, no matter if it is a piece of furniture or a major component in our cars or military supply.

Products printed illegally raise serious security issues. They could harm the safety and the security of any environment, but most concerning is the hypothesis to use them in an act of sabotage.

It is sufficient that an attacker infiltrates the supply chain of critical component to hit final users.

The above scenarios aren't speculating about a distant future, but the reality of our times. Many companies are moving to 3D print manufacturing and it is possible that the 3D blueprint file will get into the hands of attackers or criminals specialized in counterfeiting. These actors could start to mass produce counterfeit products, or in the case of an operation of sabotage, to produce specific components to infiltrate the supply chain.

Private firms and government entities are working hard to prevent this kind of threat. For example, a Texas company Quantum Materials Corp has recently announced to have licensed a technology called 'quantum dots' which could prevent counterfeiting.

The company inserts tiny nanocrystals into a product, which function as a unique physical signature that cannot be cloned and that is associated with the manufacturer. The company also implemented a further security layer based on semiconductor nanomaterials that emit different colored lights if properly stimulated.

It is clear that similar technologies could prevent 3D printed products from substituting for the original ones.

"Embedding and detecting quantum dots is an innovative way to police counterfeit goods," said Daniel Brean, a senior associate at The Webb Law Firm. "Standing alone, or as part of other digital rights management, I expect the quantum dots technology to greatly assist IP owners in preventing unauthorized uses of their technologies."

Fortunately, there are any other solutions that could be implemented to avoid counterfeiting, including shape memory polymer, anti-erasing ink, and DNA marking. It is essential that private industry and government will start to adopt them to mitigate the threats.

Conclusions

3D technology is a reality and it is in continuous evolution. Many industries are starting to adopt it due to its advantages. IT experts consider 3D printing a democratic technology that could rapidly evolve, providing great benefits to society, but as we explained, with its rapid evolution threats are also increasing and we must be prepared.

Some sectors need most of all a regulation. We analyzed the cases of weapon manufacture, but we have also to consider that 3D printing is also being used in the biomedical field. 3D printing could be used in the future to print human organs and cartilages. Another consideration of great concern is the possibility to 3D print drugs, through the assembly of chemical compounds on a molecular level. Recently a researcher at the University of Glasglow has created a prototype of a 3D "Chemputer" that is able to produce drugs and medicine. Patients will be able in a future to print medicine by themselves, but this scenario is very insidious and such capabilities could be abused by ill intentioned.

3D printing technology is rapidly evolving. Let's regulate its usage to avoid future problems and prevent any illicit activity which would exploit it.

References

https://3dprint.com/17936/3d-print-crime/

https://www.cnet.com/news/3d-printed-rifle-dubbed-the-grizzly-fires-its-first-shot/

https://www.wired.com/2014/10/cody-wilson-ghost-gunner/

https://www.cnet.com/news/congress-undetectable-3d-printed-guns-are-still-illegal/

https://3dprintingindustry.com/3d-printing-basics-free-beginners-guide/benefits-commercial-value/

https://www.techrepublic.com/article/the-dark-side-of-3d-printing-10-things-to-watch/

https://www.worldtrademarkreview.com/Blog/detail.aspx?g=3d5fdade-8639-49d4-984e-e85eb037a827